|

During last twelve years of operation, considerable improvements have been done to supplement various features of the machine. Some important features among these are:

MULTI-CATHODE SNICS:

1.A new MC-SNICS source is installed in place

of old single cathode SNICS source. The main use of this MC-SNICS source

is for AMS experiments. 40 cathodes can be put in together. We are using

it for regular beam runs also. Its use improves the statistics of beam

on target time as the time required to develop new beam is reduced to about

2 minutes. In old SNICS source it was about 4 hours. Now more beam current

can be injected in to the tandem as the beam emittance of this source is

quite low. The sequence of cathode can be accessed bidirectionally.

Typical beam currents are given below.

Beam |

FC-02 (µA) |

7Li |

1.5 |

12C |

15 |

13C |

8 |

16O |

15 |

28Si |

14 |

107Ag |

1.5 |

197Au |

20 |

MC-SNICS :

|

Resistor based voltage grading system:

The accelerator had corona based voltage grading system to define the potential both along the column support posts and the accelerating tubes. As the pelletron facility provides beams to the needs of an academic community with wide ranging research interests, the terminal potential and ion beam species had to be varied over a large spectrum. In the corona based system , large changes of terminal potential could be accomplished by use of shorting rods and changes of insulating gas pressure only. Resistors of 3 Gega ohm, 40 kV, + 2% values were used to install a resistor based voltage grading system .As a result of this upgradation voltage stability of the accelerator has improved and no shorting rods are used now for generating variations in terminal voltages. After a few year's of operation, resistances were falling off the column support posts and a new rigid mounting system utilizing the corona mounting brackets attached to the column support posts have been implemented. In the column support posts, the pair of 3 Gega ohm resistances have been connected by a flexible braid , preventing resistance breakaage due to excessive vibration which was earlier happenning.

Features

* WELWYN RESISTORS ( 3 GW, 40 kV , + 2 %)

* BETTER VOLTAGE STABILITY ( App. 2 kV IN 15 MV )

* LARGE TERMINAL POTENTIAL VARIATION WITHOUT SHORTING RODS (2.93 TO 15.3)

Charging chain monitoring system by pick up rings:

Capacitive

pick up rings were installed around the pelletron chains to observe uniformity

of charge distribution on the pellets of the chains. Monitoring of charging

chains is done with this online monitoring system and it was observed that

monitoring of the chain oscillations, chain frequency and other variations

in the signal patterns help in maintaining a long lived charging system.

* AN ON-LINE MONITORING SYSTEM FOR UNIFORM CHARGE DISTRIBUTION ON CHAINS

* SMOOTH OPERATION

OF CHARGING SYSTEM OBSERVED TILL NOW (77,000 HOURS )

Conversion of Double Unit Structure to Single Units:

The accelerator structure has its columns arranged

in terms of double units with each double unit consisting of six 11 electrode

tubes and one shorter 8 electrode tube .In the 15 UD machine on each side

there are 7 such double units and one singlet consisting of 3 full length(

11 gap tubes) and one 4 gap tube. During shorting rods operation for terminal

voltage reduction one could short only a double unit at a time. In case

of any problems one could pin point only the doublet structure. Further

during unit wise conditioning to bring terminal voltage up one had to condition

the machine by 2 units at a time. The machine units configuration has been

reorganized by connecting centre point of each 8 gap tube to a corresponding

casting plate through a GI wire. The system has functioned well and extensive

unit wise conditioning is done with this technique.

Upgradations of Beam Pulsing System

* NEW MULTI HARMONIC BUNCHER OPERATING WITH A FUNDAMENTAL FREQUENCY OF 12.125 MHZ AND USING UPTO 3 HARMONICS

* INSTALLATION OF SPIRAL CAVITY TO AVOID PHASE DRIFT DUE TO VARIATION IN FLIGHT PATH OF THE BEAM THROUGH THE ACCELERATOR* EFFICIENCY OF BUNCHING IS 50%

Installation of a new recirculating gas stripper system:* TIME RESOLUTION ACHIEVED FOR VARIOUS BEAMS IS 1.2 NS TO 2 NS.* CHOPPER AND TWD MAY ALSO BE USED TO GIVE REPETITION RATES BETWEEN 250 ns TO 2 µs.

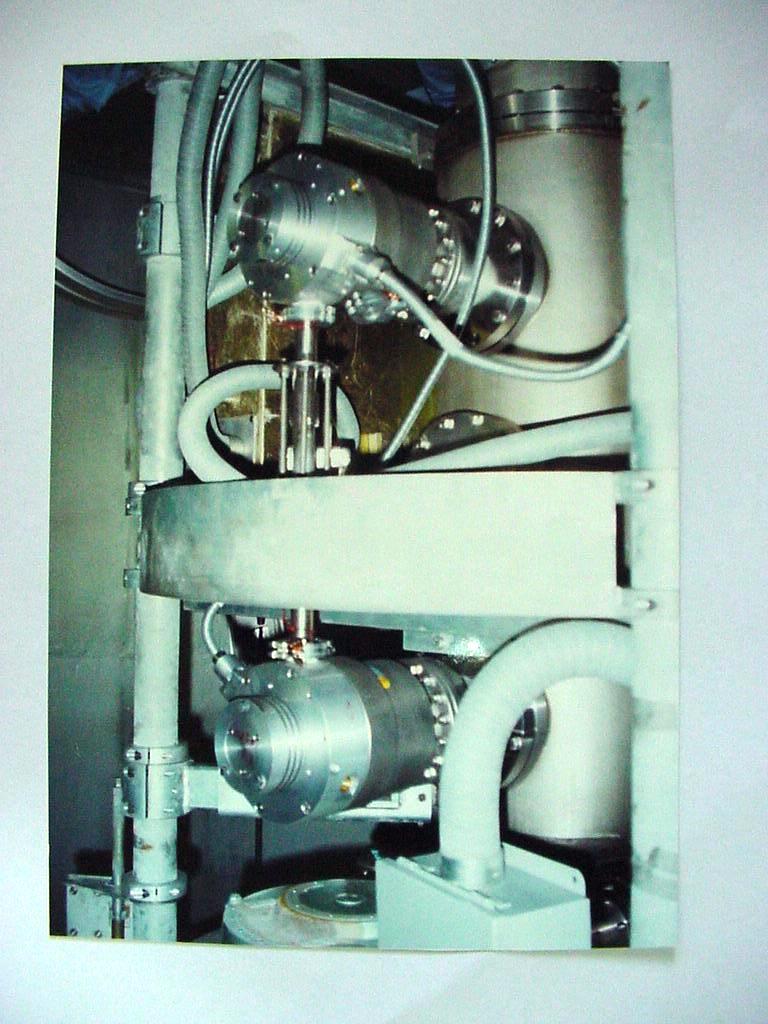

|

|

A new recirculating Turbo Molecular pump based pumping system has been designed and installed in the high voltage terminal of 15 UD Pelletron.The system has been installed and being used for regular accelerator operation .The system has helped improvements in the vacuum inside accelerator during gas stripper runs and excellent improvements in beam transmissions. Two turbo molecular pumps have been installed in place of sublimation pumps and their backing ports have been connected to the inlet line of stripper gas. The stripper gas emerges from the canal into a large volume pumped by two turbo pumps and the gas is recalculating to the stripper canal. Though the differential pumping reduces the gas escape to the accelerator tubes but any losses of gas are compensated for by introduction of fresh gas. The recirculating gas is passed through a hydrocarbon filter to prevent any hydrocarbons mixing with the stripper gas. There is significant improvement in overall beam transmissions. The machine vacuum during gas stripper operation have improved and in brief this configuration has made this machine a versatile machine. It has made possible to deliver beams of very low energies also which were not possible with previous configuration of gas stripper .

Development and installation of new foil stripper position read back system:

An entirely new system was designed, fabricated and tested in NSC to solve the problem. This system can count precisely, the position of foil stripper from 1 to 200 in increment mode and 200 to 1 in decrement mode. The new system has an electronic UP / DN counter instead of mechanical counter. This avoids the problem of incorrect reading due to slippage and counts from 1 to 200 and reset to initial count 1 for next count after 200. It also uses much improved 8 bit DAC that gives accurate and linear output and this system has local display of stripper position read back.

Stripping of Molecular Beams (e.g. MgO )

New Technique Developed:* USED GAS + FOIL STRIPPER COMBINATION FOR INCREASED BEAM CURRENT.* STRIPPING OF NEGATIVE IONS BY FOIL LEAD TO HIGH CHARGE STATES.

* COULOMB EXPLOSION & HIGH DIVERGENCE OF ATOMS. BEAM CURRENT REDUCES.

*DESIRED ENERGY E = (q+x)V , WHERE x= MOLECULAR FRACTION , OBTAINED.* GAS STRIPPER LEADS TO LOW-CHARGES STATES.*LESS COULOMB REPULSION. REDUCED DIVERGENCE.

*SUBSEQUENTLY, ATOMIC BEAM FURTHER STRIPPED IN FOIL STRIPPER. HIGH CHARGE STATE.

Example:

INPUT CURRENT: 200nA.

24MgO6+ : ANALYZED CURRENT: 12nA= 2pnA.

FOR TERMINAL POTENTIAL OF 12 MV& STRIPPER GAS PRESSURE ~ 200 micron.

IMPROVEMENT OF 50% FROM FOIL STRIPPER ALONE

Performance of the machine:

LOWEST TERMINAL VOLTAGE ACHIEVED WITH BEAM = 2.93MV.

HIGHEST TERMINAL VOLTAGE : WITH 28 Si BEAM IN TEST RUN 16 MV

WITH 107 Ag BEAM TO USER 15.75 MV

TOTAL CHAIN HOURS = 77,000 approx.

HIGHEST ENERGY BEAM DELIVERED 1O7 Ag. 270 MeV

MAXIMUM CURRENT DELIVERED

|

|

|

|

|

|

|

|

|

The accelerator on the whole is operating satisfactorily and is operating 24 hours a day. More and more developmental activities are being taken up for better performance of the machine and preventive maintenance is also carried out regularly for smooth operation of the accelerator.

| Top |

| PelletronMain Page |